Using Building Information Modeling (BIM) for a new, complex high speed rail station in Taiwan

MAA recently received the Autodesk BIM Award for BIM application on the Taiwan High Speed Rail (THSR) Changhua Station, part of a three station extension of THSR in Tianzhong Township, Changhua County. Also winning the 2013 CICHE BIM Award, this stunning station was designed by Artech's Kris Yao. To reflect Changhua's yearly flower festival and its fields of flowers, the station incorporates a floral theme, with various indoor plants and eighteen petal-like columns. These columns not only serve as symbolic emblems of this county, but also utilizes skylight through its particular structure, reflecting indirect light and illuminating the lobby and reducing energy costs. The THSR Changhua station project began incorporating BIM integration technology during early stages of the project, and used widely throughout the project, from design integration, construction, and up to information integration for operation and maintenance. According to THSR senior managers, this integration decreased costs by 20%, reduced errors by 80%, while reducing time to completion by 4%. By combining cloud data storage systems with BIM, MAA ensured rapid reviews to expedite the design process.

A new landmark high speed rail train station for Changhua

Design phase

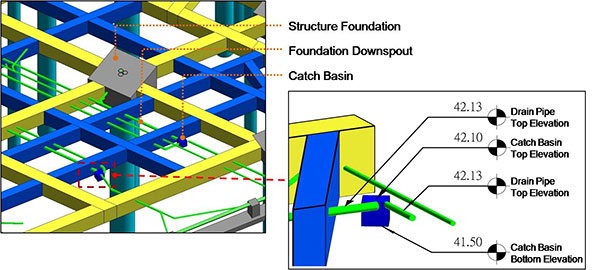

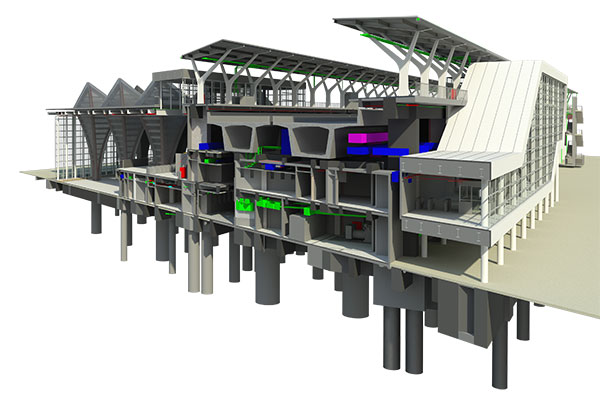

To incorporate complicated petal-like steel columns, detailed decoration and other design elements had to be carefully considered to ensure the structural integrity of the columns while preserving its form and function. By translating and integrating 2D designs into a 3D BIM model; 3D collaboration between different design teams were able to collaborate and easily recognize clashes through its 3D visualization interface. Clash detection reports and clarification reports were generated using the integrated BIM model to find potential construction issues, such as inadequate piping elevation, drainage pipeline clearance, and adequate positions between catch basins and drain pipes. Based on our clash reports, the Taiwan High Speed Rail Corporation (THSRC), reviewed the drawings submitted by the contractor, subcontractors and manufacturers to collect and correct the mistakes in the contract drawings before construction began, reducing potential on-site problems, enhancing construction quality and allowing better control over the project procedure.

Solving potential plumbing system issues before construction

Construction phase

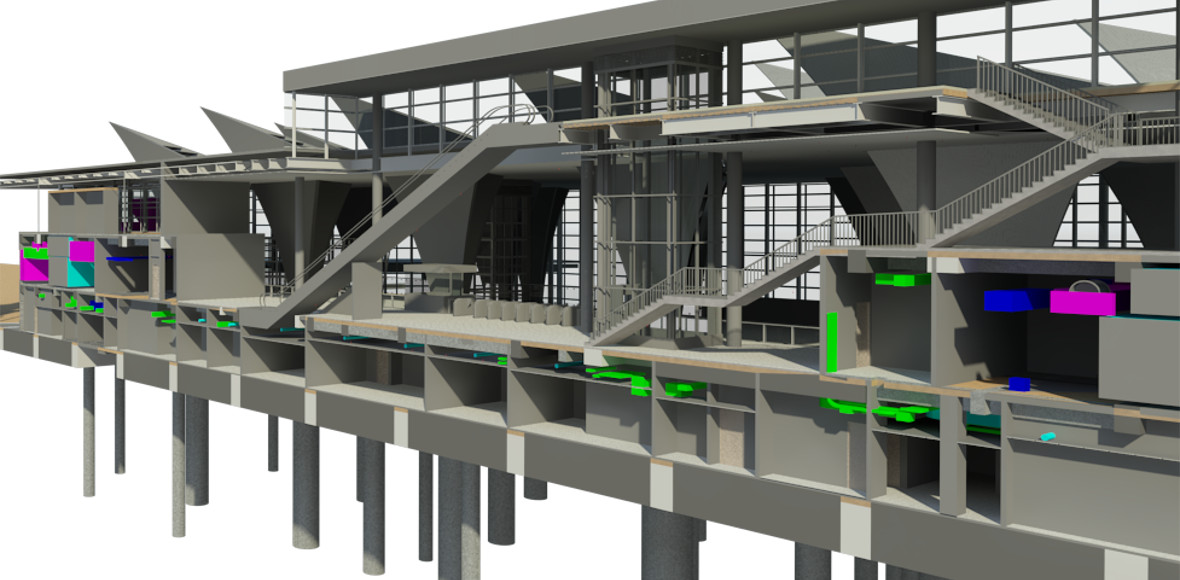

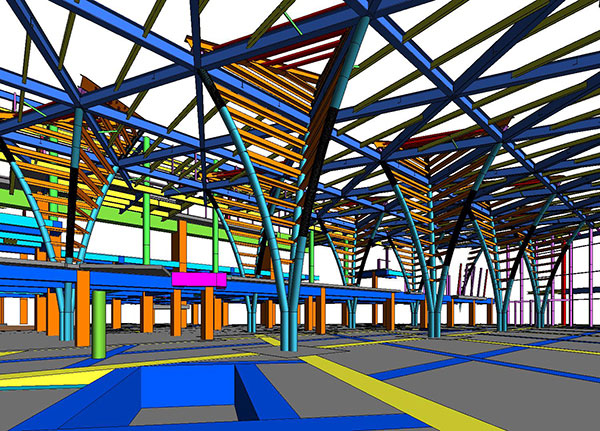

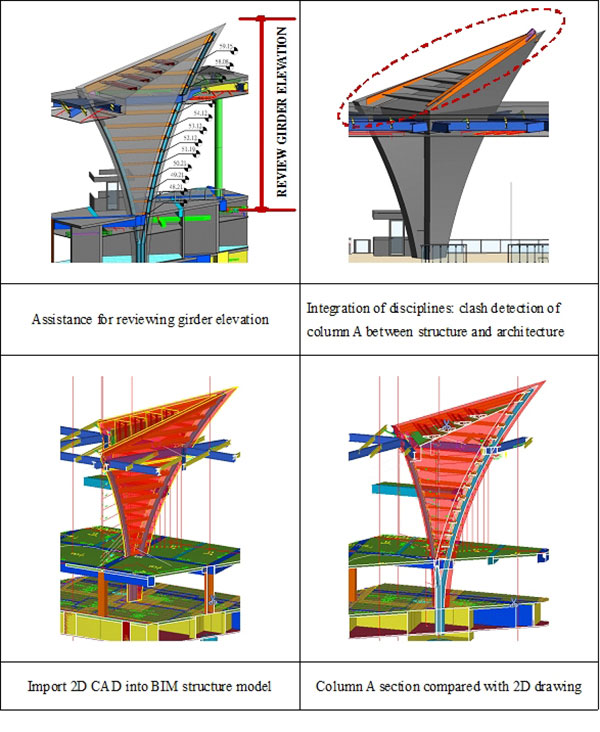

To successfully implement the signature flower blossom design concept, it was critical to integrate the curved columns with the roof curvature and MEP. MAA’s BIM center provided the sections and perspective drawings generated from the BIM model for the steel manufacturer to bring these cur petal-like columns’ steel structure.

A frozen BIM model provided a virtual platform to generate different perspective views for the steel manufacturer. The elevation of the ring girder was incorporated to the perspective views to solve any welding and on-site assembling issues. The ring girder elevation drawings from the manufacturer were also included into the frozen structural BIM model and steel construction drawings to find discrepancies. Each team member’s design was coordinated to resolve interface issues and implement clarifications on the drawings. Information gaps and labeling errors were reduced significantly for the construction stage. The design delivery, construction quality, and project management were improved significantly. Data provided by the contractors and manufacturers were also integrated into the model, providing detailed information on construction components.

The BIM model was used to help with the manufacturing of the lobby’s columns

Construction of petal-like columns

Operation and maintenance phase

After completion of the project, the as-built BIM model was used for the operation and maintenance of the train station. The model was submitted according to owner and operator’s requirements in order to increase the efficiency of management and maintenance work. By incorporating information into the model, this allowed the operator easy access to part-specific information. In addition to the engineering applications implemented throughout the complete lifecycle of the building, BIM technology provided additional benefits such as assistance to the production of high-quality animation, simulation of construction progress, and act as a visual communication platform for different departments to effectively collaborate, saving the owners time and costs, while ensuring a high quality construction.

The 3D frozen BIM model can be used for operation & maintenance tasks

Scope of Services Summary

- Create a multi-disciplinary BIM model and provide 3D visual inspection for specific areas

- Provide solutions for conflicts between architecture, structure and MEP

- Provide quantity reports of different disciplines to check quantity reports from the design team

- Provide a collaboration platform for filing, database sharing and preview

- Help clarify clashes and differences between architectural drawings and construction drawings

- Provide relevant construction drawings and information to the contractor

- Use the 3D BIM model to resolve interface issues during construction

- Improve control over project progress, material control, and on-site preparation

- Provide as-built BIM model for facility management

2D drawing integration and clash detection